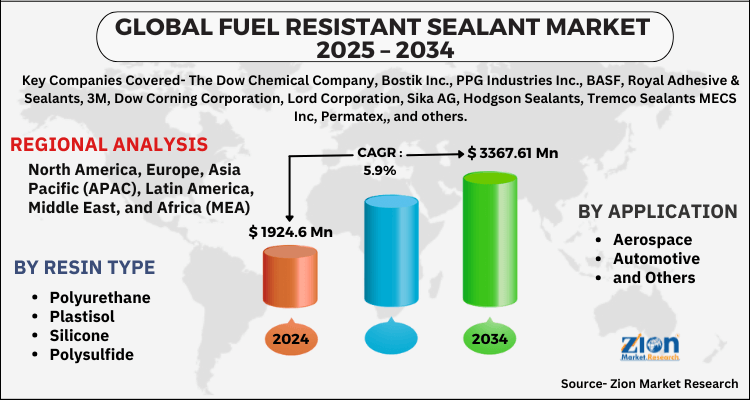

In an era defined by advanced engineering and stringent safety standards, the unsung heroes of durability—fuel resistant sealants—are gaining critical importance. These specialized formulations are engineered to create impermeable barriers against aggressive fuels, lubricants, and chemicals, preventing leaks, corrosion, and structural degradation. The global fuel resistant sealant market is experiencing significant expansion, propelled by technological advancements, rising safety regulations, and growth in key end-use industries.

Market Drivers: The Engine of Growth

-

Aerospace & Defense Ascent: This sector remains a primary driver. The relentless demand for lightweight, high-performance aircraft, coupled with rigorous maintenance, repair, and overhaul (MRO) activities, necessitates sealants that can withstand jet fuels (like Jet A-1) and wide temperature fluctuations. The push for next-generation and fuel-efficient aircraft directly fuels R&D in advanced sealant chemistries.

-

Automotive Evolution: The automotive industry’s transformation is twofold. In traditional internal combustion engines, sealants are vital for gasketing, fuel tanks, and engine components exposed to gasoline and diesel. Simultaneously, the electric vehicle (EV) revolution requires sealants that protect battery packs from moisture and coolants, while hybrid vehicles need solutions compatible with both fuels and electricity.

-

Stringent Regulatory & Safety Standards: Global regulations emphasizing worker safety, environmental protection (e.g., VOC emissions), and vehicle/aircraft operational integrity mandate the use of high-performance sealing solutions. This compliance-driven demand pushes manufacturers toward more reliable and certified products.

-

Industrial Infrastructure Expansion: Oil & gas pipelines, chemical processing plants, fuel storage tanks, and marine vessels all rely on fuel resistant sealants for containment and corrosion protection. Investment in energy infrastructure and industrial automation directly correlates with market growth.

Material Segmentation: The Chemistry of Resistance

The market is segmented by chemical base, each offering distinct properties:

-

Silicones: Dominant in high-temperature applications (up to 300°C). They offer excellent flexibility and resistance to weathering, making them ideal for aerospace and automotive engine bays. However, they can have lower adhesion to some plastics.

-

Polyurethanes: Known for superior abrasion resistance, toughness, and adhesion to a variety of substrates (concrete, metals, plastics). Widely used in automotive fuel systems, truck bed liners, and industrial floor coatings.

-

Polysulfides: A historic staple in aerospace for fuel tank sealing due to exceptional fuel resistance and flexibility. Their use is now often combined or replaced by newer technologies.

-

Epoxies: Provide extreme chemical resistance and high structural strength but are typically rigid. Used in industrial repair, pipeline coatings, and as adhesives in composite fuel cells.

-

Fluoropolymers (e.g., PTFE): Offer the highest level of chemical inertness and are used in specialized, high-performance applications.

Regional Landscape: Global Demand Patterns

-

North America: A mature market led by the U.S., driven by a robust aerospace & defense sector, a large automotive base, and shale gas activities.

-

Europe: Strong growth is anchored in advanced automotive manufacturing (including premium and EV segments), aerospace (Airbus), and strict environmental regulations pushing product innovation.

-

Asia-Pacific: The fastest-growing region, fueled by massive automotive production (China, Japan, India), expanding aerospace MRO capabilities, rapid industrialization, and infrastructure development.

-

Rest of the World: Markets in the Middle East (oil & gas) and Latin America are showing steady growth linked to industrial and transportation investments.

Challenges and Constraints

The market faces headwinds including volatility in raw material prices, the complexity of developing universal solutions for new bio- and synthetic fuels, and the need for balance between performance and environmental sustainability. Additionally, the requirement for surface preparation and skilled application can hinder adoption in some cost-sensitive segments.

Innovation and Future Outlook

The future of fuel resistant sealants is intelligent and sustainable:

-

Hybrid Formulations: Development of silicone-organic hybrids and modified polymers that combine the best properties of multiple chemistries.

-

Green Chemistry: A strong shift toward low-VOC, bio-based, and recyclable materials without compromising performance.

-

Smart Functionality: Research into sealants with self-healing properties or sensory capabilities to indicate failure or degradation.

-

EV & New Mobility Tailoring: Explosive growth in formulations specifically designed for battery thermal management, electronics potting, and hydrogen fuel cell systems.

Read More-

https://www.zionmarketresearch.com/de/report/access-mats-market

https://www.zionmarketresearch.com/de/report/3d-cad-software-market

https://www.zionmarketresearch.com/de/report/offshore-support-vessels-market

https://www.zionmarketresearch.com/de/report/digital-health-market

https://www.zionmarketresearch.com/de/report/industrial-steam-turbines-market

https://www.zionmarketresearch.com/de/report/vacuum-interrupters-market

Conclusion

The fuel resistant sealant market is more than just a niche chemical sector; it is an essential enabler of modern transportation and industrial safety. As industries push the boundaries of efficiency and environmental responsibility, the demand for smarter, tougher, and more adaptable sealant solutions will only intensify. Companies that invest in R&D to address the evolving challenges of new fuels, substrates, and regulations are poised to secure a commanding position in this resilient and dynamic global market.